What is SPC flooring?

The full name of SPC flooring is stone polymer composite flooring or stone plastic composite flooring, in Europe and the United States, it will also be called SPC flooring for rigid vinyl plank. SPC is a solid core plastic flooring, the core of the main components of calcium carbonate powder (calcium powder) and polyvinyl chloride (PVC) powder, two through the machine after the uniform mixing and extrusion, to make the SPC flooring substrate. The substrate is a composite sheet that provides a rigid and stable core structure for the floor.

What does SPC flooring consist of?

SPC flooring can mimic natural wood, stone, marble, and other veins, taking into account the practicality of the aesthetics and design at the same time, there are a variety of types to choose from regular flooring, SPC tile flooring, E.I.R flooring, herringbone flooring, and so on.

It consists of a multi-layer structure, each serving a unique function. It usually consists of 5 parts, but may vary between manufacturers:

♦ UV Layer: It protects the floor against stains, water, and UV rays and reduces aging and fading of the floor.

♦ Transparent Wear layer: protects the floor from scratches and wear.

♦ Decorative layer: Printed with different textures, colors, and patterns.

♦ Rigid core layer: gives the floor extreme hardness and toughness, preventing the floor from breaking.

♦ Underlayment pad: available in IXPE and EVA to reduce the walking noise. Is underlayment necessary?

What is SPC flooring made of?

1. Mixing

The new material of resin powder and stone powder is mixed hot and stirred according to the ratio of 1:3.3, and mixed under the high temperature of 120 degrees and high-speed mixing of 1500-2000 revolutions per minute. The high temperature and high-speed mixing ensure the stability of the base material.

Our factory strictly tests the incoming materials in this step, the quality inspector will test each batch of stone powder and resin powder to ensure the moisture content and whiteness of the stone powder are up to standard.

2. Extrusion molding

The mixed material will be extruded, this step will be the substrate and decorative color film layer and wear layer tightly combined, and the embossing roller will be embossed on the wear layer pattern processing, if it is to the EIR flooring will be scanned with infrared positioning color film mark line, to ensure that embossing rollers in the embossing can be accurately synchronized and aligned with the pattern on the color film.

The surface of the floor formed in this way not only has a real sense of touch but can also show a high degree of simulation of the visual effect.

The extrusion step also determines the length of the SPC vinyl plank flooring. Complete panels can be extruded in lengths of 1220, 1524, and 1820 mm, with a fixed width of 970 mm.

Our factory has a quality inspector at this stage to check the bending, static flexural strength, and peeling force of the flooring. If it is a return order, we also compare the sample with the newly made product to make sure that there is no color difference and that the embossing depth is the same.

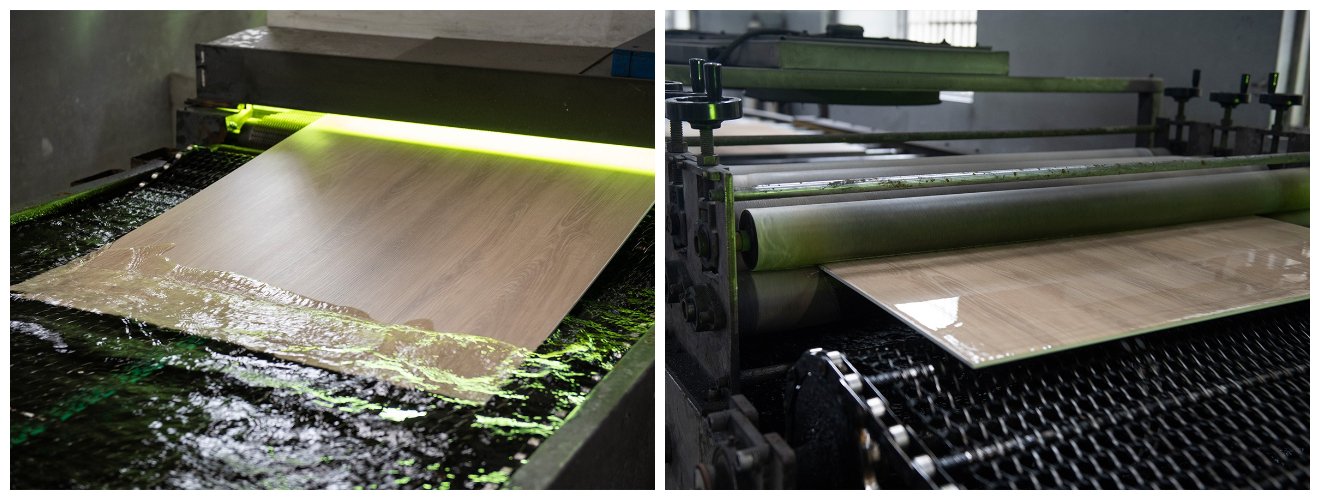

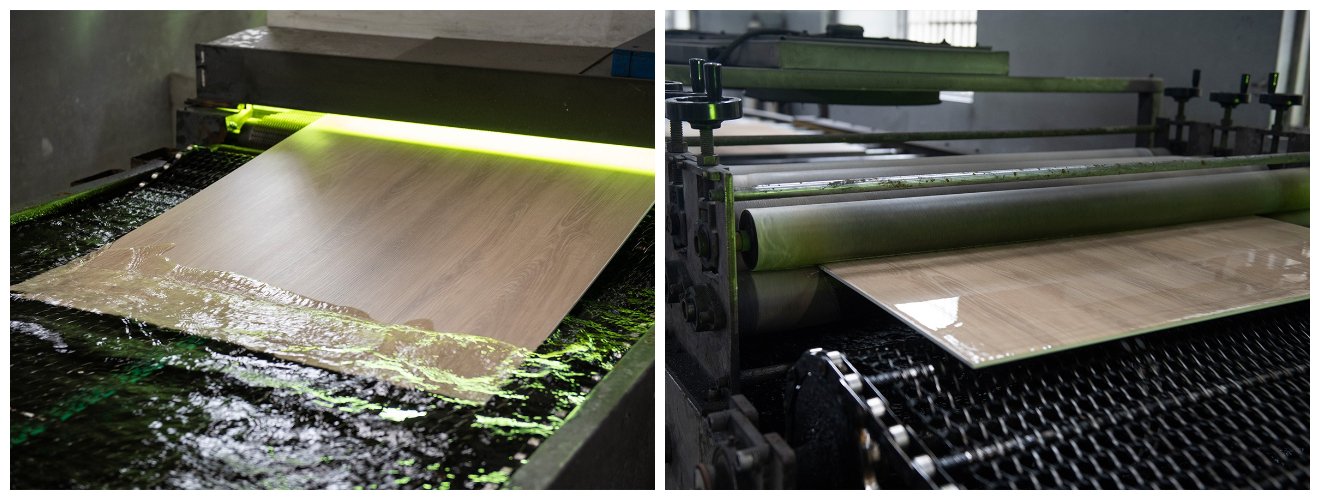

3. UV layer curing

The machine cures the UV layer on the complete board, dries the UV layer, and then cools it with water. This step determines the glossiness, abrasion, and scratch resistance of the floor, and can effectively prevent the floor from discoloration brought about by UV radiation. You can also choose to do an antibacterial stain-resistant UV layer.

Quality inspection in the UV layer production is completed will check the floor surface cleanliness and gloss and customer requirements are consistent, but also compared to leave samples and made out of the product whether there is a color difference.

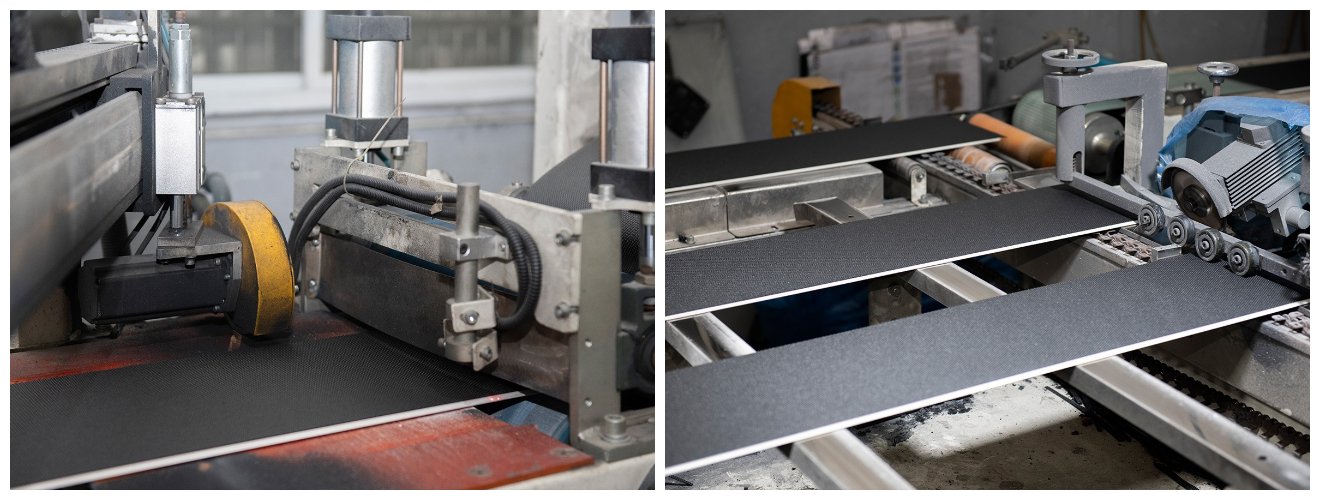

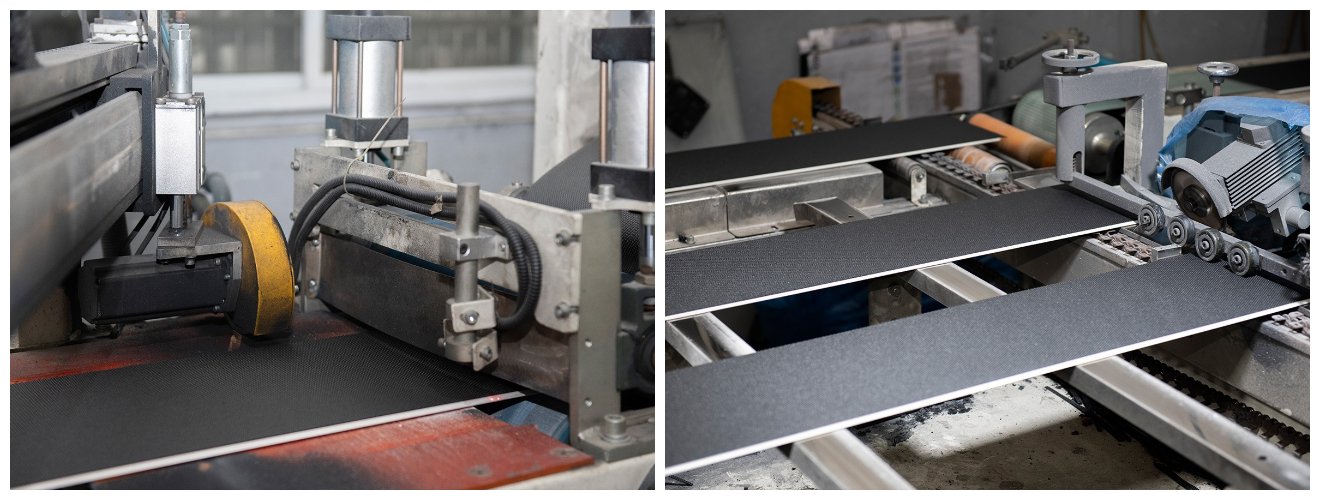

4. Cutting and grooving

The whole floor will be cut into the required width, such as 180-185mm, 228mm, or 128mm for herringbone splicing, and then slotted by the German HOMAG slotting machine for accurate slotting, you can choose Unilin, valinge, and I4F three kinds of locking system.

The quality control will interlock the grooved flooring with the retained samples to ensure that each batch of products can be perfectly spliced with the previous ones.

5. Laminating

Choose a suitable IXPE or EVA underlayment and apply it to the back of the floor, ensuring that the underlayment fits well with the SPC flooring substrate, and checking for quality after application to ensure that there are no gaps between the underlayment and the substrate.

The finished vinyl plank flooring with attached underlayment will be effective in blocking moisture and noise during subsequent use.

6. Packing

Finally, the production of good flooring is neatly stacked for packaging. In the packing process will be checked again to ensure that each piece of flooring meets the quality standards.

SPC Flooring Pros and Cons

Understanding the pros and cons of SPC flooring will help you better understand if it fits your needs and the environment of your space.

Pros:

1. 100% water and moisture resistant

2. Easy to install – Most SPC flooring uses an easy-click locking system for easy installation and removal, and many residents of Europe and the United States will do their DIY installation.

3. Wide range of choices in patterns and textures – Multiple designs for realistic visual effects.

4. Environmentally friendly – no formaldehyde, no heavy metals. Avoid using solid wood, can be recycled.

5. Fire-resistant – The floor itself is flame-retardant and can withstand high-temperature changes.

6. High Strength and Wear Resistance – The rigid core structure and wear-resistant layer can effectively resist daily wear and tear, whether it’s scratches from pets or furniture movement, it’s not easy to leave scratches.

7. Quiet – The multi-layer structure enables the floor to obtain a certain sound insulation effect.

8. Easy to clean – Simply wipe it down and it’s as good as new.

9. Environmental stability – will not expand or contract due to high or low temperatures or humidity, suitable for a variety of environments and climates.

10. Customizable – You can choose various colors and specifications of SPC flooring, almost every item has to be customized, for example, you can choose SPC flooring and panel and so on.

Cons:

1. Lack of texture – Although SPC flooring can mimic the look of a variety of natural wood and stone, the real feel may not be as comfortable as wood flooring.

2. Installation Requirements – Make sure the installation environment must be on a flat surface, and cannot be installed outdoors.

3. Cannot be repaired – the splicing method determines that it is not possible to individually replace or repair a damaged piece of flooring.

4. Not completely 100% scratch-resistant – in high-traffic areas, SPC flooring is more likely to receive scratches and abrasion, but also to avoid heavy, sharp objects directly in contact with the surface.

5. Limited quietness – Due to the hardcore material, there is often an echo when stepping on it, which may affect the user’s experience.

Comparing SPC Flooring to Other Flooring

When choosing to floor, it is vital to understand the characteristics and differences between different types of flooring, SPC, WPC, laminate flooring, and traditional hardwood flooring all have their unique advantages, I will show you: how these floors perform with different characteristics, and to help you choose the right type of flooring for your needs, budget, and usage environment.

SPC Flooring vs WPC Flooring

|

SPC Flooring |

WPC |

| Material |

Stone plastic composite substrate |

Wood plastic composite substrate |

| Hardness |

Solid hardcore |

softer wood component Slightly |

| Comfort |

Relatively hard on the feet, and easy to fatigue after standing for a long time. |

Comfortable foot feels, suitable for the home environment. |

| Water resistance |

Excellent |

Contains wood material, slightly less water resistant than SPC. |

| Installation |

Needs to be done on a flat surface |

Can adapt to unevenness |

| Scratch resistance |

Better than WPC |

Easily dented or damaged |

| Soundproofing |

Normal |

Excellent sound absorption |

| Cost |

More expensive than WPC flooring |

Cheaper than SPC flooring |

SPC Flooring vs Laminate Flooring

|

SPC Flooring |

Laminate Flooring |

| Material |

Stone-plastic composite substrate |

Multi-layer material composition |

| Water resistance |

Excellent |

Poor |

| Scratch resistance |

Better than LVT |

Excellent, but the surface is fragile and easily damaged. |

| Stability |

Excellent, will not expand or contract. |

More sensitive to temperature, overheating may cause deformation. |

| Environmental |

Not contain formaldehyde and other harmful substances. |

Not environmentally friendly, with formaldehyde. |

| Soundproofing |

Normal |

Excellent |

| Lifetime |

≥20 years |

10~20 years |

| Cost |

Normal |

High-end and low-end product prices vary. |

SPC Flooring vs Hardwood Flooring

|

SPC Flooring |

Hardwood Flooring |

| Material |

Stone-plastic composite substrates |

Natural wood |

| Water resistance |

Excellent |

Poor |

| Scratch resistance |

Excellent |

Excellent, subject to abrasion over time |

| Stability |

Not expand or contract |

More sensitive to changes in temperature and humidity, will expand or contract. |

| Soundproofing |

Normal |

Excellent |

| Install |

Easy click-locking system |

Relatively complex installation process |

| Lifetime |

≥ 20 years |

≥ decades |

| Maintenance |

Relatively simple maintenance |

Requires regular maintenance and care |

| Design |

Mimics the appearance of many natural materials |

Natural texture aesthetics that can’t be replicated, are suitable for upscale decorating. |

| Cost |

Normal |

High |

From the above comparison, it can be seen that whether it is SPC, WPC, laminate flooring, or traditional hardwood flooring, they are all the best choices.

However, SPC flooring is more cost-effective due to its excellent waterproof performance, excellent durability, and simple installation method.

SPC flooring is not easy to deform in wet environments, which makes it suitable for kitchens and bathrooms, as well as being hard-wearing and scratch-resistant, which makes it suitable for high-traffic areas. Its environmentally friendly materials are more friendly to health and do not require complex maintenance and simple daily cleaning.

In addition, SPC flooring is easy to install, with a locking design, users can complete the laying by themselves. Therefore, SPC flooring is an ideal flooring choice for both aesthetics and practicality.

Installation and Maintenance of SPC Flooring

Easy Locking Technology

Locking technology makes the installation of SPC vinyl flooring quick and easy, with no need for glue or nails, making it easy to complete a DIY installation, due to this feature, it has become the flooring of choice for many consumers and builders.

First of all, from the left corner of the room lay the first piece of flooring, make sure to leave a certain expansion gap with the wall, and then the second piece of flooring the short side of 45 ° inserted into the first piece of locking, gently downward pressure, when you hear the “click” sound, it means that the locking has been completed.

Continue to butt the long side of the second piece of flooring with the first piece and press gently to ensure that the lock is secure. Repeat until the entire room is covered.

The above steps make it easy to install SPC flooring and enjoy the beauty and durability it provides.

What are the Types of Locking Systems Available For SPC Vinyl Plank Flooring?

The locking systems are used to snap multiple floors tightly together to create a continuous, stable surface that ensures it will not loosen or move during use. To achieve a complete and uniform effect and create an overall continuous floor surface, the latch system is crucial.

Unilin, Valinge, and I4F are the three leading locking patentees in SPC’s locking systems.

Unilin is the largest patented company for locking clasps, which are usually required for flooring exported to Europe and the US, and for which you have to pay extra for the patent. Its two common types of latches are the Unilin Splicing Latch and the Unilin Push Straight Drop Latch.

Valinge is another well-known patented buckle company and its buckle types are 2G buckle, 5G buckle, and 5G buckle with inserts. 5G lock is a slap buckle and 2G is a splicing buckle.

Our flooring utilizes 5G locks, a technology that allows flooring pieces to be easily butted together during installation utilizing a precise tongue and groove design that eliminates the need for glue or nails. Simply insert the short edge of the flooring into the latch of the previous piece and gently press the long edge until the latch closes tightly, making it ideal for modern floor coverings.

I4F has a slightly larger consumable locking system, similar to Unilin, with a wider tongue and groove for the locking clasp, which requires more edge material to hold against the tongue and groove structure. It is designed with a short edge tap fastener and a long edge plug fastener to provide a more stable splice structure.

Cleaning Method

SPC flooring is very easy to maintain, due to its multi-layer structure characteristics, with waterproof, anti-fouling, wear-resistant features, the daily maintenance process requires only a simple sweeping, vacuuming, and mopping to complete the floor cleaning.

1. Regular sweeping or vacuuming, use a broom and vacuum cleaner to clear the dust and debris.

2. Damp mopping, mopping the floor with neutral detergent and the right amount of water, and keeping the floor dry after mopping.

3. Spot clean freshly emerged stains, using a mild detergent.

4. Avoid bleach, ammonia, and any strong solvents that may damage the floor.

To keep SPC flooring as good as new during long-term use, you need to pay attention to preventing heavy objects from directly pressing on the floor, especially in the area of frequent use, you can consider placing a carpet or mat to reduce wear and tear. Also, try to avoid walking on the floor in shoes with sharp heels to minimize unwanted scratches.

In areas with heavy foot traffic, clean regularly and adjust the frequency of cleaning as appropriate to prevent dust and dirt from causing long-term damage to the surface of your floor. Only through these meticulous maintenance measures can you ensure that your SPC vinyl flooring stays as good as new for the long term and extends its service life.

Conclusion

SPC flooring because of the tightening of environmental protection policies in Europe and the United States came into being environmentally friendly flooring, and traditional flooring is different, a collection of fire-resistant, waterproof, and recyclable and so many advantages, and environmental protection concepts appropriate at the same time is a stable, good and pro-family flooring.

Bofei SPC Manufacturer

As a professional SPC flooring manufacturer and supplier, we are committed to providing our customers with the best quality flooring solutions, we always pay attention to the needs of our customers and provide customized services to meet the requirements of various commercial and residential projects, to ensure that each piece of flooring obtains excellent quality, providing realistic wood grain and stone grain patterns and textures to help you create a beautiful and comfortable living environment.

You can get an up-to-date quote by filling out the form and sending us an email, and we will provide you with a free consultation to help you choose the perfect SPC flooring that can meet your needs.